The E-type Jaguar was a very advanced car for its day. Not only was it a styling revelation, it also brought a lot of “high tech” bred on the racetracks of Europe to the street. It was the first car to bring four-wheel disc brakes, a fully independent suspension, and a monocoque/tube-frame chassis to the market. One other, not as well-known innovation was fully electric instrumentation – with the exception of the cable-driven speedometer all instruments were analog predecessors of today’s digital dashboard. The oil pressure, temperature, and fuel gauges were driven by electrical sensors and senders. The tach was driven by a small AC electrical generator located on the intake camshaft. The spinning camshaft generated X-voltage per revolution which translates to needle movement on the tachometer.

Much in the way that today’s goofy digital car accessories will drive car collectors and restorers of the future absolutely insane (Many a BMW customer is confused by the iDrive system, and they have a manual to RTFM… can you imagine some poor slob 75 years from now trying to decipher it without any reference materials at all?) these now-primitive analog electric gauges drive us crazy today. They were high-tech stuff fifty years ago (no more routing hot engine oil into the passenger compartment!) but add a layer of obsolescent complexity to maintenance in the present. The generators and other analog components eventually weaken with age and start producing erratic signals. My tachometer is no exception and based on my built-in “aural tach” I could tell that mine was off.

Jaguar, to their credit also noticed this issue over time and went to a distributor-driven tach not long after my car was built.

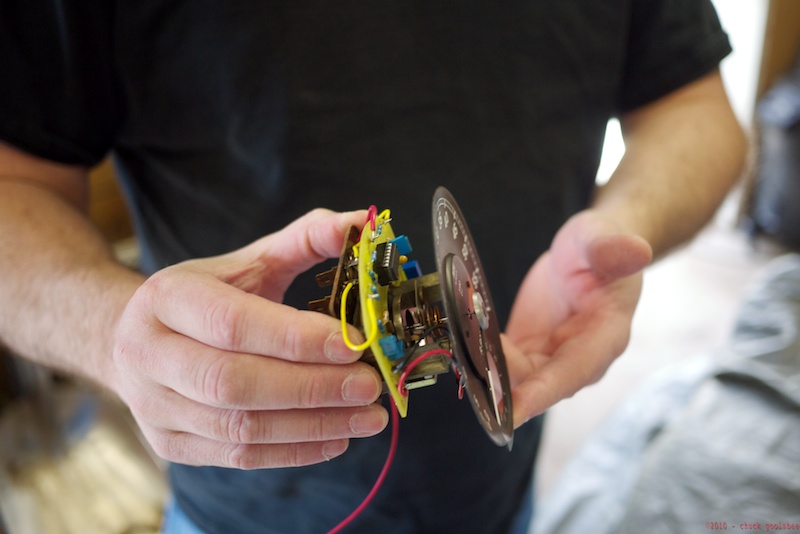

I hang out online with a bunch of old guys on the Jag-Lovers.org E-type forum/mailing list, many of whom have been maintaining these cars since the first started coming out of the factory in Coventry… three years before I was born. I really could not survive E-type ownership without them. They are an incredibly knowledgeable, resourceful, and helpful group. One of them, a gentleman in Cornwall, England by the name of Dave Rawle has solved the problem of the early Series 1 tachometer. I purchased one of Mr. Rawle’s circuit boards last year with the intention of adding it to my “winter projects” list. Of course winter came and went, and life prevented me from coming near, much less completing my list. The impending arrival of “driving season” has me now scrambling to get the list at least half-done.

Unfortunately this installation required soldering.

I retired from soldering shortly after learning how in Junior High Electronics class. The story involves permanent disfigurement and everlasting shame which I won’t share with you at this time. As Dirty Harry said, a man’s gotta know his limitations, and I know mine stop short of soldering.

Thankfully I know somebody who could probably make art out of solder in his sleep: Jim Cox He used to work for me at digital.forest many years ago, but before he was an IT guy, he was an Electronics Technician in the aerospace industry. I called Jim and asked if he would be willing to help me out, and he said yes. I handed off the tach, the circuit board, and the instructions to Jim a few weeks ago… and I suspect he stared at it stressfully for two weeks. Jim’s a very conscientious guy, and I think he genuinely feared screwing up this sensitive antique gauge. Having read the instructions myself, I knew the job was pretty straightforward, and well within Jim’s skills. If anything it would be a super-simple task for him. I inquired on his progress now and then … and heard hesitation in his replies. I gently pushed him, and reminded him of my complete trust in his skills. Sure enough last weekend I started getting progress reports from Jim over AIM/iChat. Then, a triumphant series of messages arrived, indicating that Jim had installed the board successfully. We arranged a time for him to come up to Arlington to help install it in the car.

Another one of my “winter projects” is to have the Jaguar’s clock repaired. As the clock is integral to the tachometer’s housing I planned on doing them at the same time. Unfortunately the clock project has hit a brick wall (more on that another time, in another post) so the tach installation here will be a temporary one – just enough to get the car operational again. I showed Jim how the tach works and after a trip to NAPA to get some parts we needed (electrical connectors, and some washers) I set up a work table for Jim in the barn’s doorway.

Yes, that “table” is a dead Xserve… don’t ask.

Jim built a new cable with an inline fuse for the new tach circuit board, along with a few extension cables so we could ground and test the new unit prior to actually installing it into the dashboard. Jim did the electronics work while I did the actual installing stuff into the car.

I wired in the tach and held it in my hand and started up the car. It works!

It is always such a massively satisfying feeling when stuff works properly. I watched the tach while running the car through various rev ranges that my ear is tuned to and made an initial judgement that things were working properly. Of course the proof is in the actual driving, so we cleaned up our work space and went out for a drive. First stop was in Arlington for a lunch. On the way the tach worked perfectly and was accurate to the speedometer through the gears. After lunch we went east into the mountains and had a great drive up by Lake Cavanaugh and Pilchuck Creek, the latter half with Jim at the wheel.

I think he liked it.

Oh I liked driving the Jag, I liked it a lot! Thanks for opportunity of not only driving the Jag, but also for working on the tach. Yeah I was a little scared, but once after all was said and soldered I looked back and realized I had a blast doing the work. It was a great confidence builder and helped me get my geek back. Cheers ~ Jim