In the last post in this series I discussed testing & reaction. After the processor is finished I move the whole mixture into my wash tank and let it sit for a week or so. The glycerin settles and I drain it off the bottom.

Next comes washing. Washing is a step whose aim is to remove impurities from the BioDiesel. Even after it settles for a week, the BioDiesel has impurities in it. These are mostly in the form of microscopic food particles. Washing assists in removing these. Again, I am not a Chemist, I just play one at home on the weekends, so the following may not be true, but here is what I understand happens: Water droplets attract the impurities as they fall through the water as the food particles are hydrophilic. The wash tank puts a fine water mist above the BioDiesel. It falls and collects on the surface of the oil then falls through the oil to the bottom. Along the way it picks up impurities.

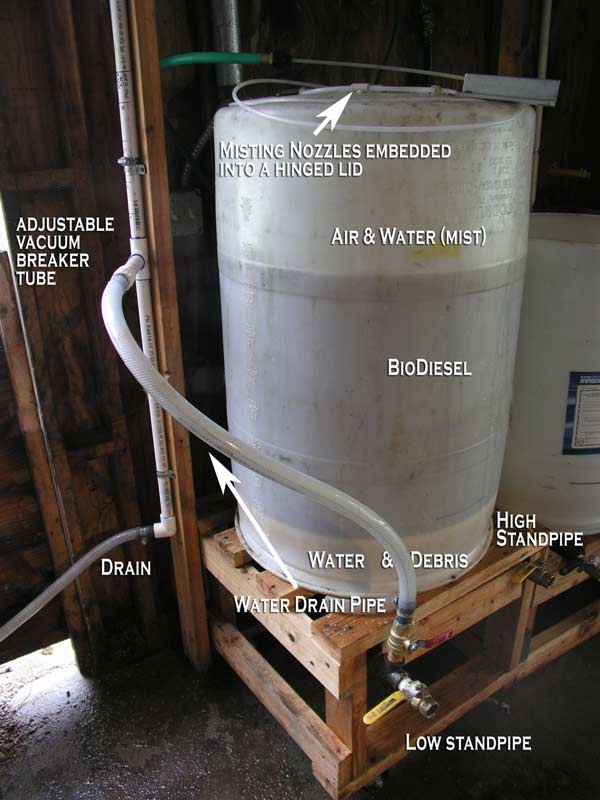

I have a continuous mist wash tank. This utilizes a drain pipe with an adjustable vacuum tube. By moving the tube up or down I can control the level of liquids in the tank and prevent it from overflowing. Dirty water drains out, but oil is kept in. The water collects in a barrel outside the barn.

I run the water through until it runs clear. At first it is grey and cloudy as you would expect water mixed with a lot of potato and flour particles. Eventually it clears up as the impurities are removed from the BioDiesel.

When the wash is complete the BioDiesel is now contaminated with water. This however is easier to deal with than food particles as separating what is basically oil & water is pretty easy. You can let it sit for an extended period of time, or you can “dry” it. I’ve done this both ways, and that will be the subject of the next post in the series.

I mentioned before that washing is a mildly controversial issue among home brewers. There are risks involved, the primary one is emulsification. This is when your BioDiesel turns into a cream-colored glop that looks like pancake batter. From what I understand this is caused by an incomplete reaction and/or the presence of soap. Washing also involves using water and in some parts of the world water is a scarce thing. I’m not too worried about the latter living here in the Pacific NorthWET. I have had issues with emulsions, and in fact I stopped washing through this entire past winter. Instead I’ve been letting my fuel sit in vented storage barrels to settle. Now I’m washing again and my quality seems to be going up. I think my main issues before was not taking enough time. Time is on my side and I just have to be patient. Allowing the processed BioDiesel to sit for a few days before washing seems to really help. Building my drying tank has taken it that much further.

Next up: Drying washed BioDiesel.