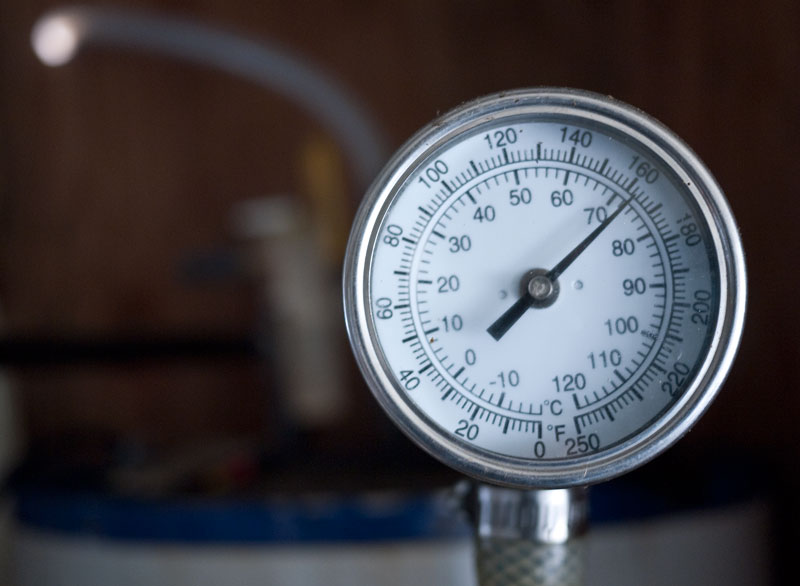

I’m cooking up a batch of BioDiesel today. Filled up the processor last night and and turned it on to heat up. Obviously my thermostat is off calibration as it is supposed to stop at around 55°C. Easy fix.

For the past year I’ve been doing a two stage process, with an 80% load of the catalyst going in first, followed by an overnight settle, then a re-heat and the remaining 20% going into the mixture. This seems to get better conversion rates, though slightly lower yields – which even to my pea-brain understanding of Chemistry seems to be logical. Since I started doing this two-stage process I have yet to have a batch go bad in the wash process. Nothing worse than watching 100+ liters of fuel turn into a vat of pancake batter, or soap!

The downside is that it takes twice as long to do the processing as you have two overnight settling times. I’m happy to see 2—5% lower yields since I’m getting better fuel in the end. Warmer temperatures are coming soon, which means I can run the cars on more home-brew and less pump fuel. The old TDI gets switched to B100 as soon as ambients hit the 60s (F), but Sue’s CRD tops out at around B80. I just haven’t worked up the courage to commit her car to 100% home-brew.

This winter it thankfully never stayed too cold here so I was able to keep at least 20% BD in the tanks of both cars, which keeps the fuel systems clean and avoids filter clogging that inevitably haunts us if any car has reverted to 100% #2 Diesel. That stuff coming out of the pump just coats the tank with crud without some good veggie solvent to keep it clean.