I’d always heard that BioDiesel had a tendency to clear out the accumulated crud in your fuel tank and system. Now I know it for a fact. Last weekend Sue called me from Skagit county complaining of a significant loss of power. I’ve had her Jeep Liberty CRD running on about a max-B20 mixture for a while. I had noticed my B50/B90ish VW Jetta TDI hesitate now and then as well. I considered the possibilities. Clogged filter? Or have I brewed up a batch of crap?

I drove up to Skagit in the TDI and took her car home to experience it for myself. The car started and ran fine, but when you really got on the throttle, merging onto a freeway for example, it just bogged down and just… would… not… go… Very frustrating. I got off the freeway and went the rest of the way home on back roads so as not to cause an incident. I noted that if I gradually accelerated it would be fine, up to whatever speed I wanted. But if I laid into it, or climbed a steep hill it acted as if it was towing a huge load. I parked the Jeep in the garage and went into town later to the NAPA store to buy a new fuel filter cannister. Being a Diesel it uses a big honkin’ filter combined with a water separator. In fact it has all sorts of sensors attached and even had a “water in fuel” idiot light on the dash to tell you to drain it. The NAPA didn’t have one and in fact it had to be shipped from out of state. They said 3 days – in the end it took a week. They did have one for the Jetta so I grabbed one of those, just in case.

I look like a genius in hindsight because later in the week I went to start up the Jetta and it took some serious cranking to get going. It also bogged a bit a couple of times when underway at freeway speeds. The “check engine” light also illuminated. Great.

So the Jeep filter finally arrived today and I started the process to change it. The Mopar Morons routed a power steering hose and several electrical wires all around the filter cannister so it was a royal PITA to get off. The water sensor disconnect can only be reached from directly underneath so I ended up soaking my arm in Diesel while trying to get it off from under the car. Grrr. If I had miniature hands I could have done it from above I guess, but being born with Y chromosomes I have big meaty mitts that could only get to it from below at full arm extension. =\

Car designers should have to work on the cars they make!

The one bit of forethought they put into it was a handy spring pump on the housing and bleeder nipple to prime the filter with fuel without a mess. Too bad I was already soaked in Diesel anyway!

Sue of course took off in the Jetta before I was done wrestling with her Jeep. Sure enough she calls me from Stanwood. The Jetta conked out on her while on the freeway. The Jeep unfinished, I jumped in the old pickup truck we keep in the barn for lumber and hay hauling duties (retired from trailering when she sold the horse trailer) and drove up there to rescue her. The Jetta drives fine for me all the way home but I figure I’ll swap its filter too.

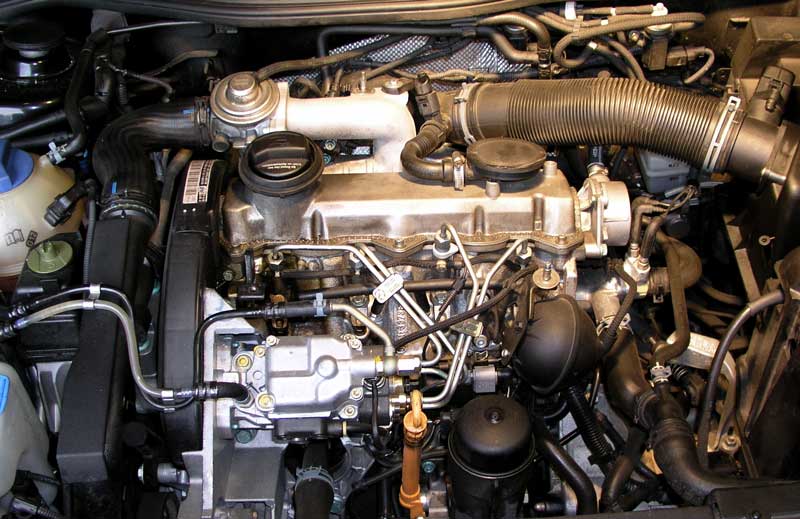

I finish the Jeep and take it out for a test drive. It runs like a top. Lots of acceleration and no hesitation whatsoever. I take it out on the freeway just to be sure and decide to drop it off for Sue at the horse place and take the pickup home. I then swap the Jetta’s filter, which is an under-5-minute job, unlike the Jeep’s. No priming pump, so it is a tad messy, but I already reek of Diesel so who cares. Fire the Jetta up in the garage. Starts right up and no check engine light anymore.

Just out of curiosity I take the filters out to the barn, grab a hacksaw and open them up:

Here is the Jeep’s filter. It started out as a very light beige color (you can see a little bit of untainted filter element at the top right.) As you can see it is filthy.

Above is the Jetta’s filter. It was even worse than the Jeep’s. It has big gloppy sludgy bits in it.

I guess I’ll buy another pair, or maybe four of them to keep on hand as the tanks clear out their accumulated sludge.